Cloud & Edge computing platform & services

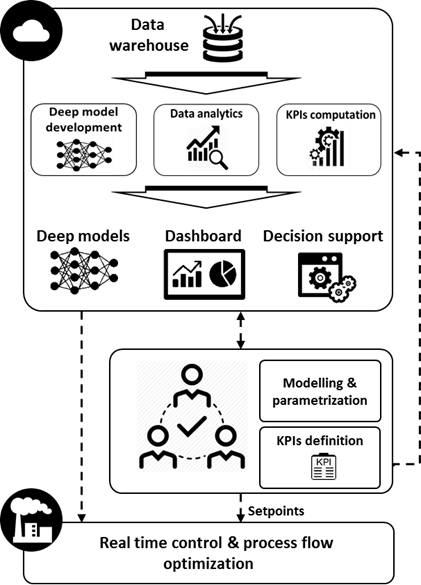

MULTIPLE will establish an integrated production optimisation framework allowing flexible control of the production line, applying real-time control at specific critical points (e.g. PID controller at machine level, automated production flow rerouting based on quality checks), as well as monitoring the overall production efficiency providing meaningful information (e.g. energy/material consumption, costs) for decision making and feedback to update production models and KPIs. This will be integrated in configurable dashboard for the end-users.

Relying on the information and data collected and stored in the scalable cloud data warehouse -raw and real-time data processed from the photonic monitoring solutions developed in MULTIPLE, together with other data coming from different sources already present in the factories (e.g. PLCs, SCADA, ERP)- and the power of the open source Elastic Search Engine and cloud micro-services, MULTIPLE will provide effective tools to analyse data and compute KPI and enable product quality and consumption traceability.

Such solution will facilitate to locate fault sources providing decision support feedback for adjustment and correction, reducing intervention times, and alerting production managers. The integrated system will apply big data analytics to have a better understanding of complex production processes involved in the production lines. This will improve the accuracy of the simplified models used for real time control and finding more accurate, but complex, deep models, or re-defining KPIs.

MULTIPLE will deal with the integration of monitoring systems and the optimisation of production. This includes the development of closed-loop control and RT data-driven production optimisation.

The specific objectives are:

- To integrate the multi-modal monitoring systems in production processes.

- To design and develop on-line process and quality control system.

- To develop data analytics and the decision support system for production optimisation.

The multi-modal monitoring systems will be integrated in the machines and production lines, whenever possible as a new part of the existing machine and whenever necessary as turnkey system suitable for its installation in the production line of the factory floor. Integration of the illumination systems will also be tackled.

In a first stage, existing machine parameters and monitoring systems that should be also taken into account for process optimisation will be integrated in the orchestration scheme by deploying edge computing devices as needed and ingesting the corresponding streams of images, measurements, and parameters in the data warehouse.

In a second stage, the core devices will be integrated in the factory floor at the different end users, as well as the process optimisation tools. A special attention will be given to the interfacing of the multi-modal monitoring systems in the process.

The implementation on the embedded platform will guarantee a time deterministic execution of the RT monitoring and control system and the machine to machine operation.

Build on top of the architecture developed with the support of MRA will develop the solutions tailored to the monitoring and control needs of end-users. This will involve the development of all the connectors, dashboard options, and front-end clients to deploy the reporting and decision system that supports:

- Business intelligence based on KPIs and data analytics

- Process flow control

- Anomaly detection

- Alarms

This system will take advantage from the Kibana and Elastic Search engine that provides data visualisation and analytics as core of the business intelligence. Custom functions will be implemented to support RT streams processing for anomaly detection and firing of alarms (e.g. drift in production, foreign body).

Custom plugins and micro-services will be implemented to complete the analytics and decision support system, taking into account the workflows and needs defined by the industrial partners that supply and integrate manufacturing equipment and production lines.

Moreover, we foresee to enrich the analytics capabilities, for the breakthrough hyperspectral data cubes provided by the HSI sensors, by supporting the use of visual semantic embeddings. This offers unique opportunities for the automatic analysis and discovery of new knowledge from hyperspectral imaging stored in the data lakes, with implications at different levels like to the creation of complex models that interrelate different production stages and are fed by different monitoring sources, and to the extraction of improved process indicators.