Woodworking

Monitoring solutions to optimise the process in furniture manufacturing

For the woodworking processes, the MULTIPLE project aims to implement the technologies to measure parameters such as humidity, density and the elasticity of the raw input material both before and during the processes as well as defect detection and colour inspection of the finished product.

MULTIPLE will implement its photonic-based process monitoring technologies in a woodworking process to manufacture furniture and to enable an early reaction to problems in specific parts, detecting defects as they appear and taking corrective measures (e.g. reworking, reclassification), before the component undergoes further processing. Parameters that will be monitored include humidity, density and the elasticity of the raw input material both before and during the processes as well as defect detection and colour inspection of the finished product. The system will collect data from different furniture components to build a reference bank using the Data Warehouse. An adaptive close-loop control will be implemented for adjusting the operation using the HSI vision system and estimated parameters (i.e. uniform glue distribution, localised defects, and wrong border colour) to automatically adjust the machine. The edge device will be integrated with PLC of the machine. As a result, the main optimisation goals in this wood working use case will be enabling one-size batch with zero defect, maximising the reuse of residue, and minimum delivering times, in order to minimise cost and meet the main trends of the market, driven by online retail channels and online exposure.

First results

July 2020 – First trials with ROYO’s wooden boards samples

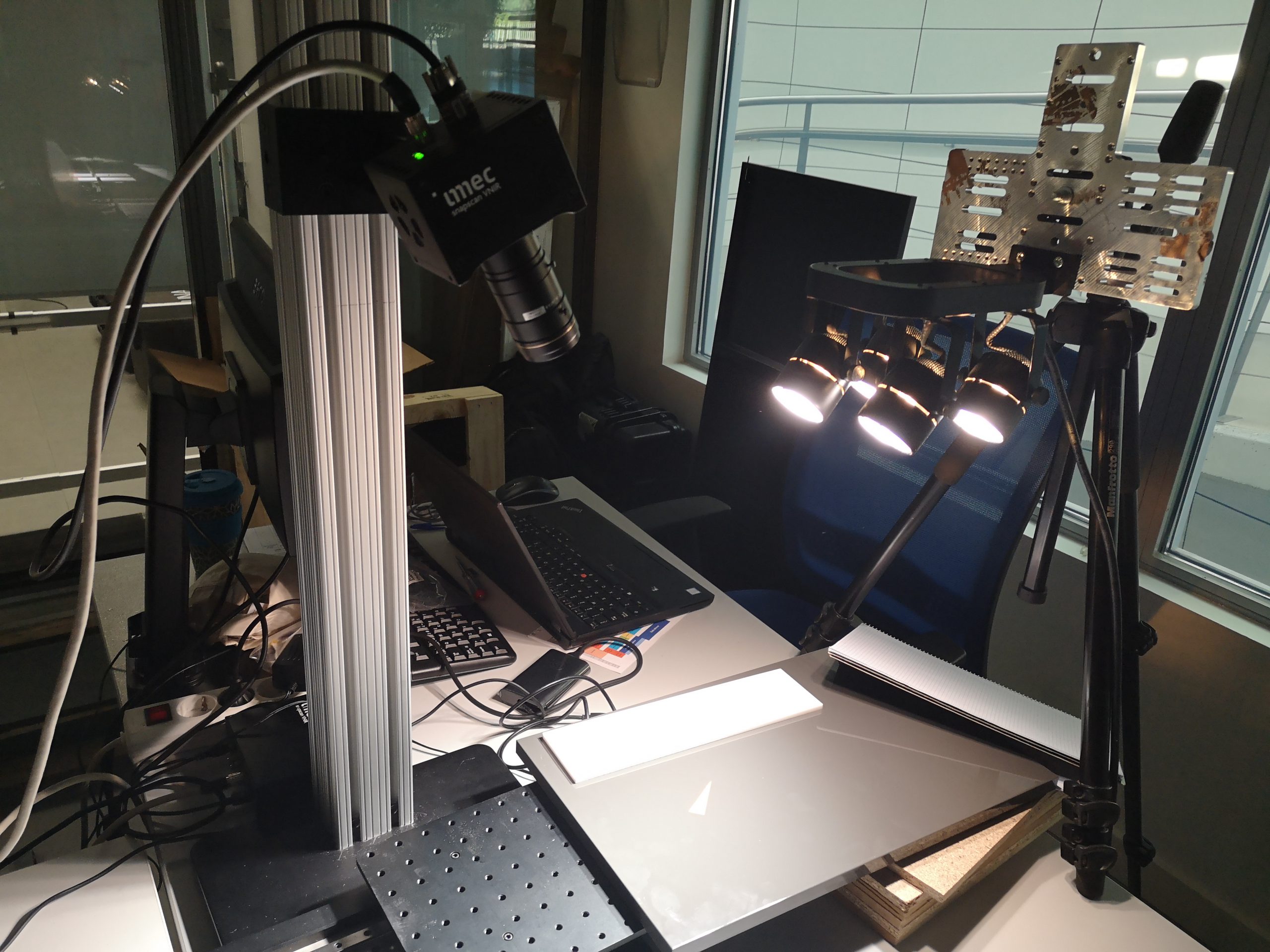

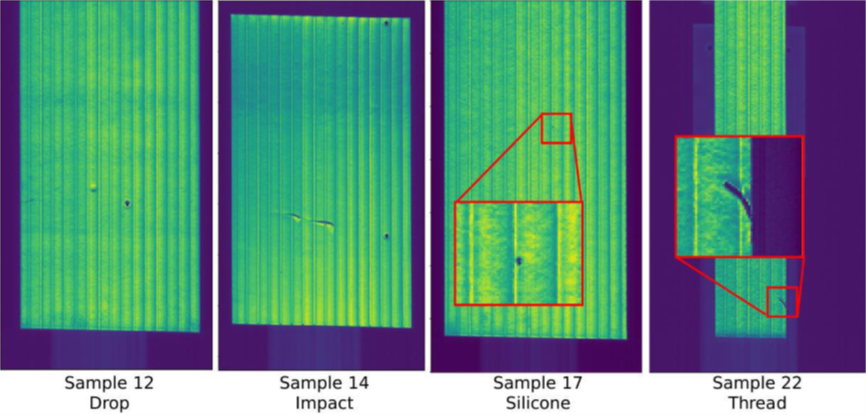

AIMEN has been performing the first tests using IMEC’s hyperspectral camera (Snapscan VNIR) with ROYO’s wooden boards samples to check if defects can be detected using this type of camera. Different set-ups were tested playing with camera position and lighting, and images for all the defects were taken evaluating afterwards, if it is easy, doubtful or improbable to detect these defects in an automated way.

November 2021- Moisture and primer layer quantification

The feasibility of applying classical regression model for the measurement of parameters including the detection of the moisture content, presence/absence of primer layer, and quantification of the amount of primer coatings applied in the woodworking use-cases (ROYO and ELMAG) has been studied by IRIS. Three different parameters have been assigned to be evaluated. The first one is the moisture content in the entry lacquering line. Promising result was attained, however, more data is needed to decrease the model error and have a more representative model. The second parameter is the detection of the presence/absence of primer layers on the wood in the lacquering line. But also, data from the real environmental should be collected to ensure the capability of the model. Finally, the quantification of the applied primer layer has been applied on the woodworking cases. The regression model show, however, that more data should be acquired to increase available useful information.

Integration in ROYO

Quality control monitoring system – Defects detection

AIMEN team visited ROYO facilities for the first integration in May 2021. During this first integration the preliminary prototype of the quality control monitoring system using a HSI linescan camera in the visible range was installed for early acquisition of data samples. Based on the results of the analysis of the first datasets, the system set-up was redesigned and optimized, being finally integrated in ROYO in October 2021. This time the system included 2 snapshot mosaic HSI cameras in the visible range. An edge computing device to control the cameras and manage the data acquisition remotely was also integrated at ROYO’s facilities.

In parallel, a deep learning processing pipeline based on state-of-the-art convolutional neural networks (CNNs) has been implemented for defect detection and classification in lacquered wood panels. Semantic segmentation and fully convolutional classification networks have been prototyped, trained, and preliminary validated with a reduced dataset containing laboratory samples acquired with the first camera prototypes. The amount of labelled data available was not sufficient to properly train the neural network architectures but preliminary results are promising. From now until the end of the project the classification and segmentation models will be periodically retrained and feed with new data continuously coming from the production lines thanks to the edge-cloud.

Quality control system new prototype.

Images samples from the dataset labelled with bounding boxes.

July 2021- Colorimetry lab trials

The goal in MULTIPLE is to use a snapshot HSI visible camera as an imaging spectrophotometer enabling the measurement of device-independent color coordinates. Colorimetric models for computing color coordinates in standard CIE color spaces using a snapshot mosaic HSI camera in the visible range were developed. Two models for computing CIE XYZ values (reflectance-based and direct linear method) and perform tests to determine whether a snapshot HSI camera can be used to accurately measure changes in color similarly to an industrial spectrophotometer were developed. The models have been tested and validated with synthetic and real laboratory measurement. The results obtained are promising for the application, however, further work is required to validate the findings under real environmental conditions.